Lean Farming: Defects

Understanding Defect Waste in Lean Farming

What Is Lean Farming?

Lean farming is an agricultural approach rooted in the principles of lean manufacturing, which originated in Japan through the Toyota Production System in the mid-20th century. Initially developed to streamline automotive production, lean methodology focuses on maximizing value while minimizing waste to improve efficiency, reduce costs, and enhance product quality.

In the context of farming, lean practices aim to optimize every step of the cultivation process by eliminating non-value-adding activities, improving workflow, and fostering continuous improvement. This approach is especially valuable in sectors like cannabis cultivation, where precision, compliance, and resource management are critical to success. By applying lean principles, growers can better manage labor, reduce input waste, and ensure consistent, high-quality yields.

Defect Waste

The goal is to maximize efficiency while minimizing waste. One of the most costly and disruptive forms of waste is defect waste. This includes work or products that fail to meet quality or compliance standards. These defects can arise from improper cultivation techniques, equipment malfunctions, or human error. They often result in significant setbacks for growers.

Reworking Systems and Work Flow

First, defects lead to rework, requiring additional labor and resources to correct mistakes. Every small deviation that forces a team to spend time fixing mistakes instead of growing triggers rework with costs time and money, and puts your plants at risk for quality degradation and damaged crops.

Examples: improperly mixed nutrients, incorrect irrigation schedules, inadequate pruning, a variable canopy that filters light unevenly, culling runt plants, and improper employee training.

Delays in Production

Next, defects cause delays in production timelines. When crops fail to meet quality standards, harvests may be postponed. This disrupts supply chains and reduces overall efficiency. These delays can be especially costly in cannabis cultivation, where timing is critical for potency and compliance. Moreover, defects contribute to lost yield, directly impacting profitability.

Plants that don’t meet health or regulatory benchmarks may need to be discarded. This reduces the total output and wastes valuable inputs like water, nutrients, and energy. One solution to this problem is to create controlled checklists for each stage of cultivation. Proper training of your team is also critical to address these issues.

Unfortunately, a tight production schedule does not always do right by your plants. Examining the counter measures you can take may vary depending on your product and work flow.

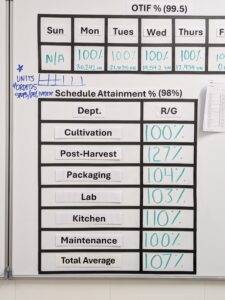

The real measure of success is repeatability, leading to a consistent quality and yield of your product.

Be Proactive

Ultimately, addressing defect waste requires a proactive approach—implementing quality control systems, training staff, and using automation where possible. Defects typically cost you 3x more in labor, morale, and yield. By minimizing defects, lean farming operations can maintain high standards, reduce costs, and ensure consistent, high-quality yields.