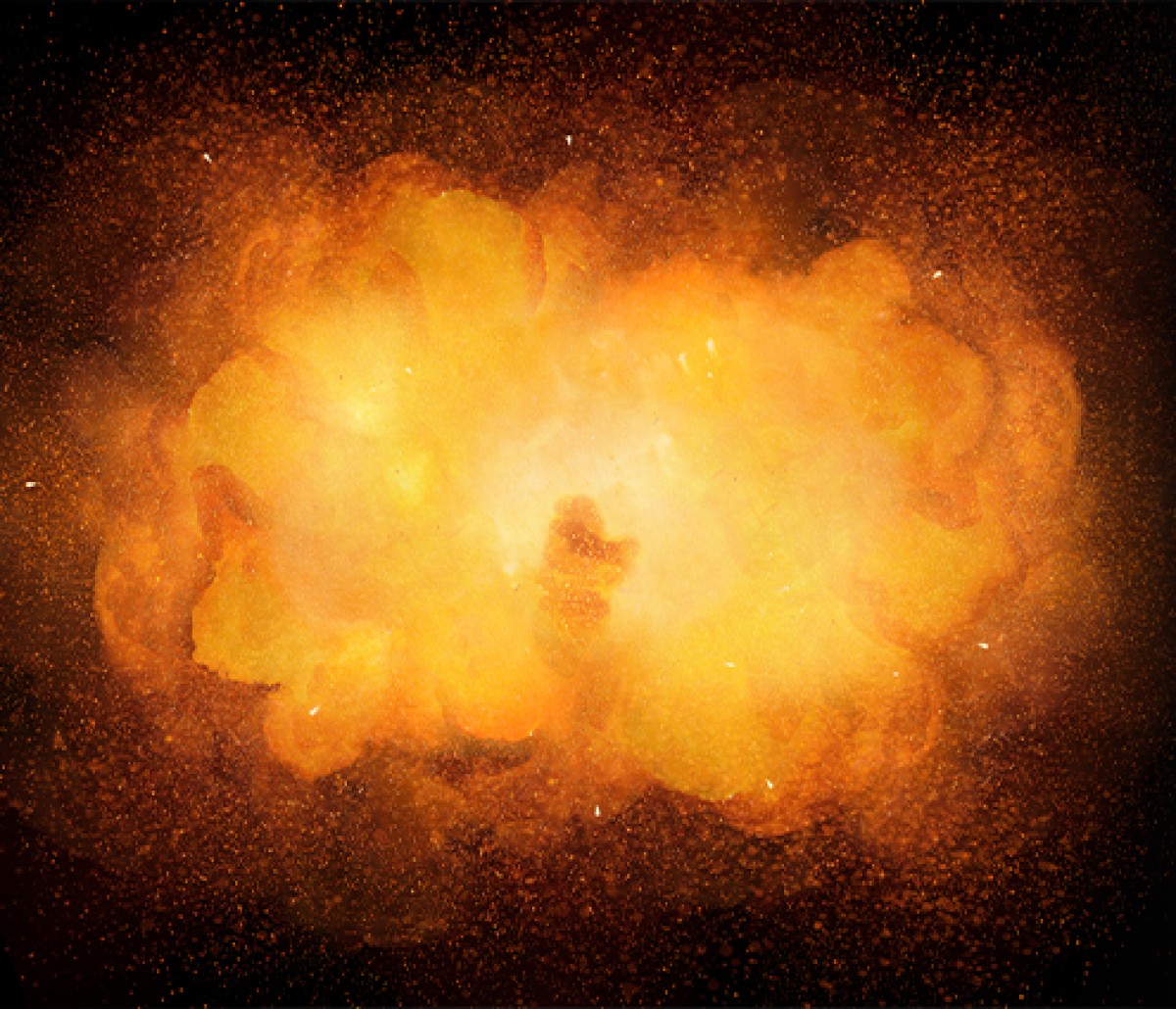

Combustible Dust: Warning!

Is Your Cannabis Operation at Risk?

Understanding Combustible Dust

Combustible dust explosion potential is one of the most overlooked risks in cannabis processing facilities. Many operators focus on product quality and licensing, failing to address Occupational Safety and Health Administration (OSHA) standards related to combustible dust which could result in serious hazards, costly fines, or even the shutdown of operations.

What Is Combustible Dust?

“CD” refers to fine particles that present an explosion hazard when suspended in air under certain conditions.

These particles can originate from organic or metal materials, including wood, grains, plastics, and cannabis. Dust is commonly generated during grinding, trimming, milling, and processing of plant material. When accumulated in confined spaces or air systems, these particles can ignite if exposed to an ignition source.

According to OSHA, combustible dust is defined as “a solid material composed of distinct particles or pieces, regardless of size, shape, or chemical composition, which presents a fire or deflagration hazard when suspended in air or some other oxidizing medium.”

Many cannabis operators are unaware that OSHA’s General Duty Clause applies to “CD” risks. Even though OSHA does not have a cannabis-specific combustible dust standard, it enforces regulations through the National Emphasis Program for “CD” and may cite employers for failure to manage known hazards.

As more cannabis processing plants scale up, the risk of combustible dust increases significantly. Operations that include high-speed grinders, drying rooms, and enclosed storage bins are particularly vulnerable. Inadequate housekeeping, poor ventilation, and the presence of ignition sources such as static electricity or machinery sparks can lead to a catastrophic event.

Guidelines and Enforcement

OSHA has issued detailed guidance on combustible dust hazards, drawing from consensus standards such as those developed by the National Fire Protection Association.

Inspections may focus on several elements, including:

- Housekeeping practices

- Ventilation systems

- Dust collection equipment

- Employee training and awareness

- Fire and explosion prevention systems

Even if a facility passes local fire inspections, that does not exempt it from federal OSHA enforcement. A surprise OSHA inspection can lead to fines and mandatory corrective actions if hazards are found.

Common Sources of Combustible Dust in Cannabis Facilities

- Trimming and Milling Areas: High-speed trimmers and milling machines can create fine plant particles that easily become airborne.

- Grinding and Drying Operations: Dry cannabis becomes brittle, and grinding it produces even finer particles that accumulate on surfaces.

- Packaging and Weighing Rooms: Residual product dust can accumulate in tight corners and under equipment.

- Dust Collection Systems: Without proper maintenance, these systems can become ignition points themselves.

- Storage Bins and Conveyors: If not regularly cleaned, these areas can harbor “CD” in large quantities.

Key Safety Measures to Reduce Risk

Cannabis business owners and facility managers can take proactive steps to manage combustible dust risks:

1. Conduct a Dust Hazard Analysis (DHA)

A DHA is a formal assessment that identifies locations where combustible dust may exist, evaluates the risk, and outlines mitigation strategies. All facilities handling combustible dust are required to complete a DHA.

2. Improve Housekeeping Protocols

Regular and thorough cleaning is essential. Surfaces, overhead beams, and hidden crevices must be inspected and cleaned routinely. Use industrial vacuums rated for combustible dust instead of brooms or compressed air.

3. Upgrade Ventilation and Dust Collection Systems

Installing high-efficiency particulate air filtration, spark arrestors, and explosion-proof vacuums can help reduce airborne dust levels. Ensure all systems are regularly inspected and cleaned.

4. Implement Ignition Source Control

Eliminate or manage potential ignition sources such as exposed electrical wiring, non-explosion-proof fixtures, and static discharge. Grounding equipment and using anti-static materials can significantly reduce the risk.

5. Train Employees on “CD” Safety

All staff should understand the hazards of combustible dust and be trained in emergency response, safe equipment use, and proper cleaning techniques.

6. Develop an Emergency Response Plan

Have a fire prevention and response plan in place. Coordinate with local fire departments and train staff on how to react during a dust-related incident.

Insurance Considerations

Insurers specializing in cannabis operations often review “CD” safety protocols as part of their risk assessment. Poor housekeeping or inadequate hazard controls can lead to increased premiums or denied coverage. By implementing OSHA-aligned safety practices, cannabis businesses can lower their risk profile and access more favorable insurance terms.

Cannabis processors, cultivators, and manufacturers must take initiative to understand combustible dust hazards and align with OSHA and NFPA safety standards.

Proactive compliance is not just about avoiding fines it’s about protecting employees, safeguarding property, and ensuring long-term success in a competitive and highly regulated market.

If you’re unsure whether your facility meets OSHA’s combustible dust standards, consult with a safety expert or industrial hygienist experienced in cannabis operations. An investment in safety today could prevent a disaster tomorrow.

Visit www.CannabisRiskManager.com to schedule a free risk assessment.